WEIGHING SYSTEMS DESIGNED WITH AGRICULTURE’S UNIQUE REQUIREMENTS IN MIND

Every day, agricultural producers harvest benefits from our legendary, reliable scale performance. Whether the application is indoors or outdoors, stationary, or mobile, our products have stood the test of time on thousands of farms worldwide and are ready to handle any agricultural environment.

With over 250 years of history, Avery Weigh-Tronix designs, manufactures, markets, and services a broad range of high-quality weighing products and systems. These products can be found in virtually every industrial environment worldwide.

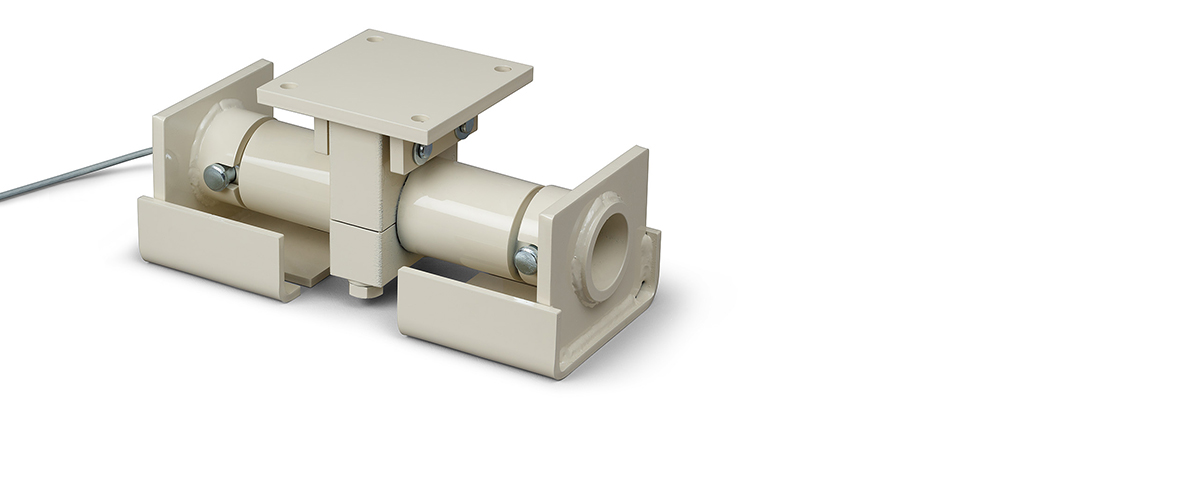

Avery Weigh-Tronix is a developer and manufacturer of weighing products and systems for customers with varied needs. We helped pioneer the weighing industry from mechanical to electronic technology with the introduction of the Weigh Bar® weight sensor.